Wholesale Paraxylene Experiment - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen

Wholesale Paraxylene Experiment - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen Detail:

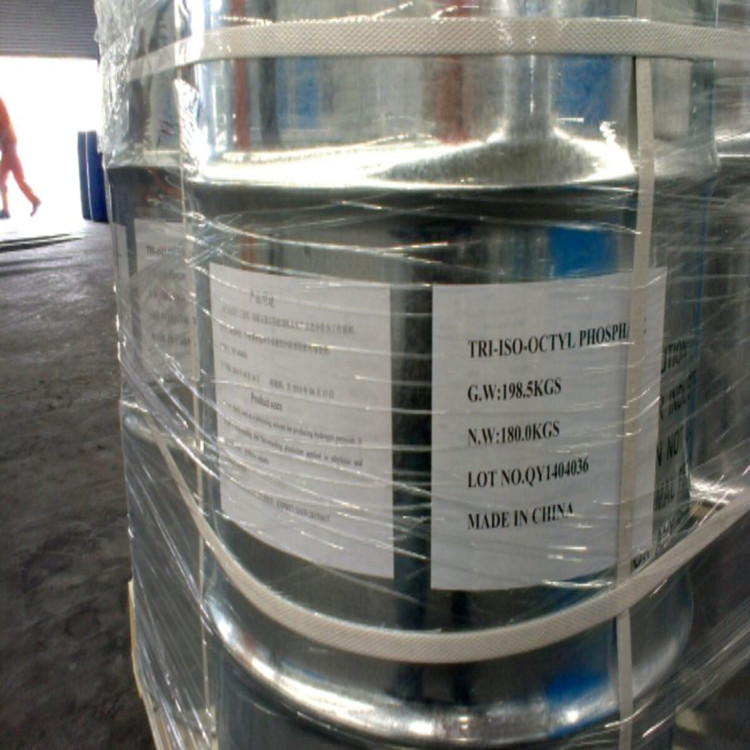

Package

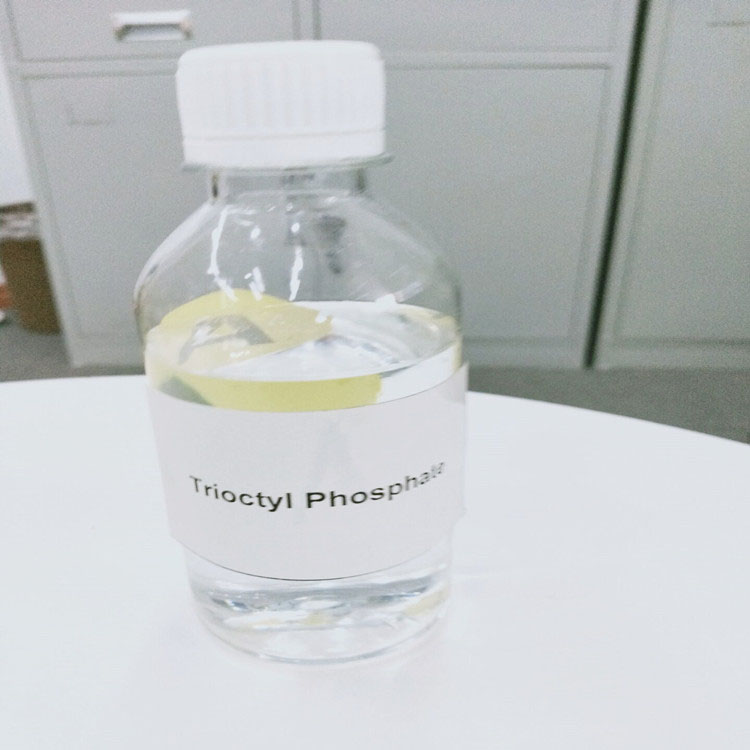

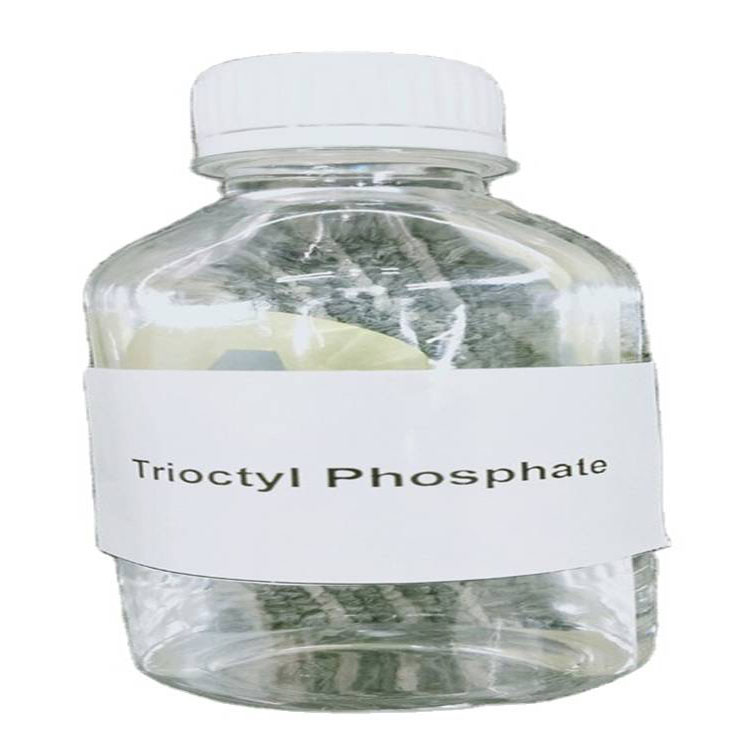

| Appearance | Colorless, odorless, transparent viscous liqui |

| Purity | ≥99% |

| Acidity | ≤0.1 mgKOH/g |

| Density (20℃)g/cm3 | 0.924±0.003 |

| Flash Point | ≥192℃ |

| Surface tension | ≥18 Mn/m |

| Water content | ≤0.1% |

| Color( Pt-Co) | ≤20 |

Package

Packaged in 200 liter galvanized iron drum, N.W 180 kg/drum; or IBC drum, N.W 930KG.

Storage

Stored in dry, cool and ventilated warehouse.

Packing

Product detail pictures:

Related Product Guide:

During the past few years, our business absorbed and digested state-of-the-art technologies the two at home and abroad. Meanwhile, our firm staffs a group of experts devoted to your development of Wholesale Paraxylene Experiment - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen , The product will supply to all over the world, such as: Ottawa, Norwegian, Nepal, Our company has abundant strength and possesses a steady and perfect sales network system. We wish we could establish sound business relationships with all customers from at home and abroad on the basis of mutual benefits.

Product quality is good, quality assurance system is complete, every link can inquire and solve the problem timely!

Write your message here and send it to us