Hot-Selling Experimental Rectification - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen

Hot-Selling Experimental Rectification - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen Detail:

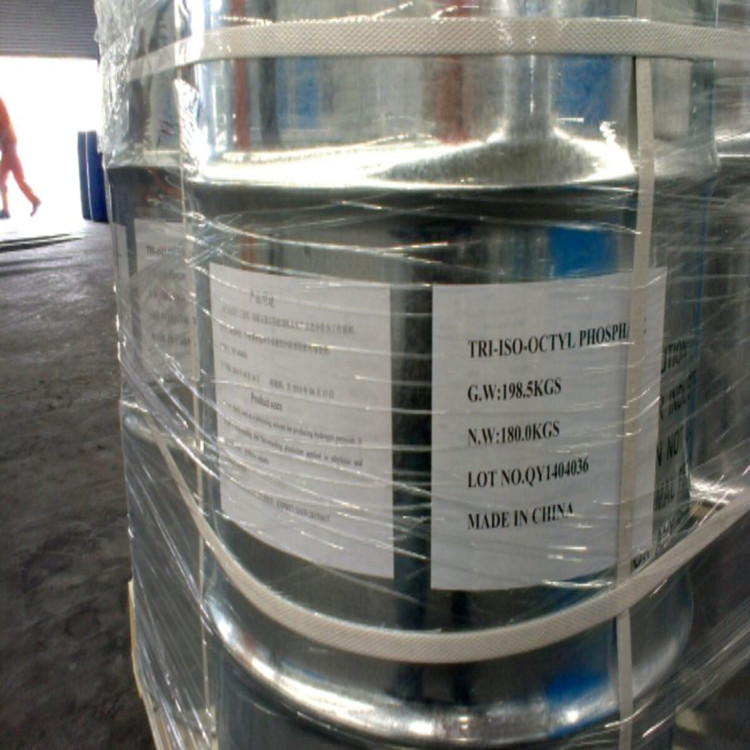

Package

| Appearance | Colorless, odorless, transparent viscous liqui |

| Purity | ≥99% |

| Acidity | ≤0.1 mgKOH/g |

| Density (20℃)g/cm3 | 0.924±0.003 |

| Flash Point | ≥192℃ |

| Surface tension | ≥18 Mn/m |

| Water content | ≤0.1% |

| Color( Pt-Co) | ≤20 |

Package

Packaged in 200 liter galvanized iron drum, N.W 180 kg/drum; or IBC drum, N.W 930KG.

Storage

Stored in dry, cool and ventilated warehouse.

Packing

Product detail pictures:

Related Product Guide:

Our commission should be to provide our customers and consumers with ideal top quality and aggressive portable digital products for Hot-Selling Experimental Rectification - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen , The product will supply to all over the world, such as: Canada, Qatar, Lahore, Our products are mainly exported to Europe, Africa, America, the Middle East and Southeast Asia and other countries and regions. We have enjoyed a great reputation among our customers for quality products and good services.We would make friends with businessmen from at home and abroad, following the purpose of "Quality First, Reputation First, the Best Services."

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!

Write your message here and send it to us