High Definition Catalyst Performance Test - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen

High Definition Catalyst Performance Test - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen Detail:

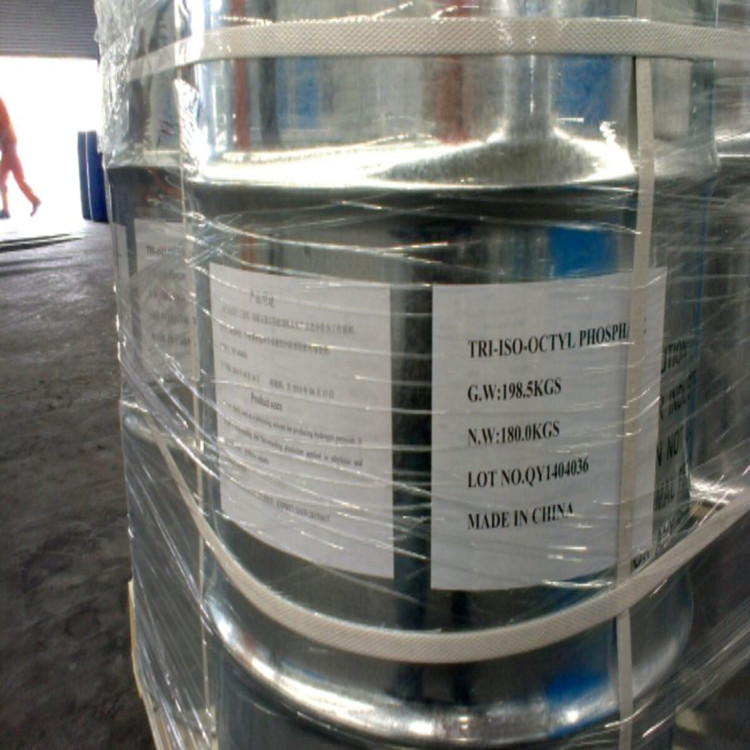

Package

| Appearance | Colorless, odorless, transparent viscous liqui |

| Purity | ≥99% |

| Acidity | ≤0.1 mgKOH/g |

| Density (20℃)g/cm3 | 0.924±0.003 |

| Flash Point | ≥192℃ |

| Surface tension | ≥18 Mn/m |

| Water content | ≤0.1% |

| Color( Pt-Co) | ≤20 |

Package

Packaged in 200 liter galvanized iron drum, N.W 180 kg/drum; or IBC drum, N.W 930KG.

Storage

Stored in dry, cool and ventilated warehouse.

Packing

Product detail pictures:

Related Product Guide:

To create much more price for clients is our company philosophy; purchaser growing is our working chase for High Definition Catalyst Performance Test - TOP, Tris(2-ethylhexyl) Phosphate, CAS# 78-42-2, Trioctyl Phosphate – Zipen , The product will supply to all over the world, such as: Grenada, Sydney, Bogota, Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers' satisfaction is our future!

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.

Write your message here and send it to us